Failure Analysis

Metallurgical Failure Analysis

Metal fracture symptomatic of a problem – unfavorable stresses and strains, improper heat treatment, metallurgical flaws, improper design or perhaps a device simply has exceeded its useful service life. Initiating corrections is based upon a proper diagnosis. Reading and understanding the fracture surface, evaluating the alloy microstructure and studying a component’s performance represent a few of our analytical tools. Completion of a project occurs when our clients receive a clean and succinct report of the technical findings.

Recent Projects

RIG COLLAPSE

Investigation revealed that the weld failure was a consequence of an indirect overload on the rig mast.

TUBING FRACTURE

Longitudinal tubing split – the joint was dropped downhole. No Material defects were discovered and the properties satisfied API specifications.

Degradation of a tank battery catwalk.

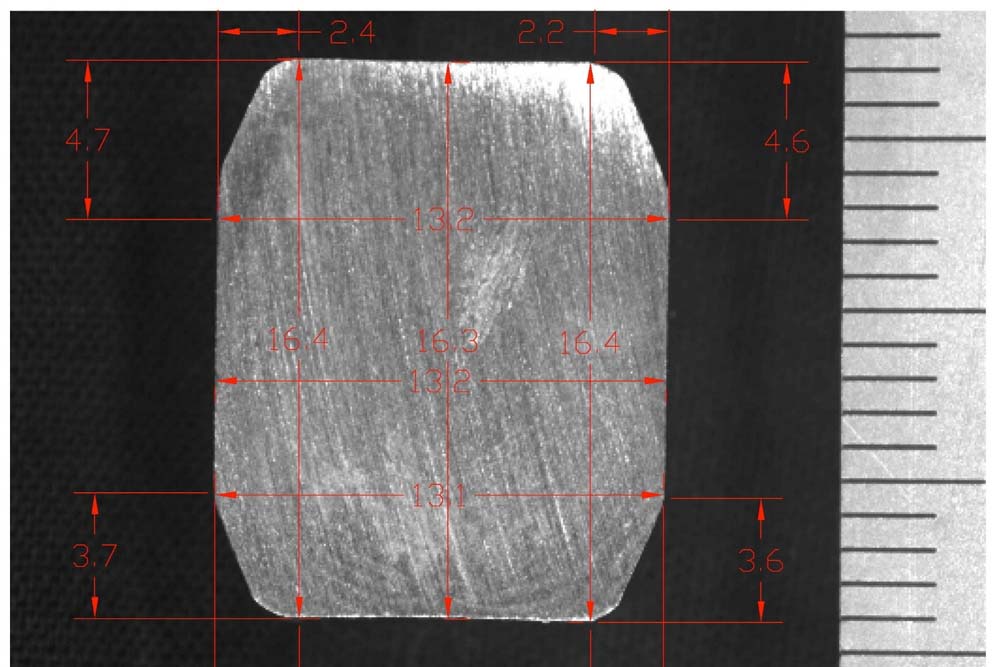

Profile of a stainless steel ring gasket. Dimensions beyond the cited tolerance lead to improper seating.

Need Our Expertise?

AME OIL & GAS

Phone 405-447-2234

Email: info@ameoilgas.com

Copyright Ⓒ All Rights Reserved | Designed by LocalPull